Covering Houston Garage Floors, Patios,

Warehouses and More, Since 2003!

"WHEN QUALITY & ATTENTION TO DETAIL ARE REQUIRED" TM

281-849-3070 CALL OR TEXT FOR POLYASPARTIC GARAGE FLOOR,

PATIO & COMMERCIAL FLOORING!

The Partial Chip

Epoxy Floor Package

This Package Includes Grey 100% Solids Epoxy with a

Partial

Distribution of Chips thrown onto the Top Surface of the Epoxy & then it is Sealed with Polyaspartic Clear Coat (Diamond Blade Grinding, Crack & Hole Filling Included!)

$995 - 1 Car Garage (up to 200 sq ft & $4.95 Thereafter)

$1,995 - 2 Car Garage (up to 400 sq ft)

Only $4.95 Per Ft Thereafter

Details on the Partial Chip Epoxy Floor Package:

-Diamond Blade Grinding

-Crack & Hole Filling Included

-10 Mils of Labsurface 100% Solids Epoxy. 100% Solids Labpoxy is an Industrial Grade Material that does not shrink because it contains zero thinner in it.

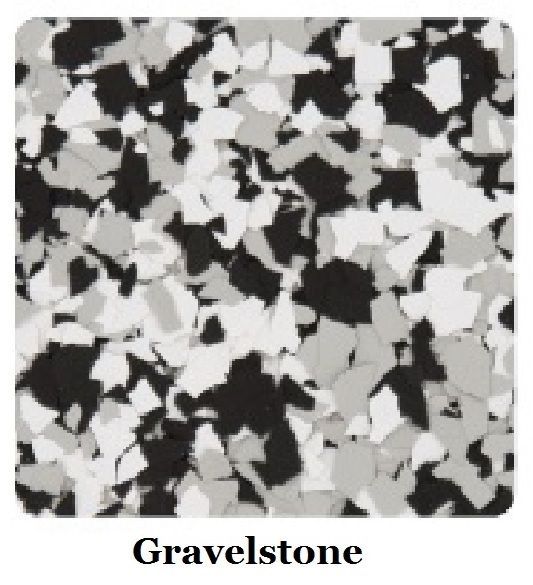

-A Partial Coverage of 1/4" class size flakes in the familiar White, Black and Grey Color Combination.

-Clear Top Coat of Labsurface Polyaspartic

-No Peel Warranty

See Our Next Floor Coating Option BELOW:

The Heavy Chip

Polyaspartic Floor Package:

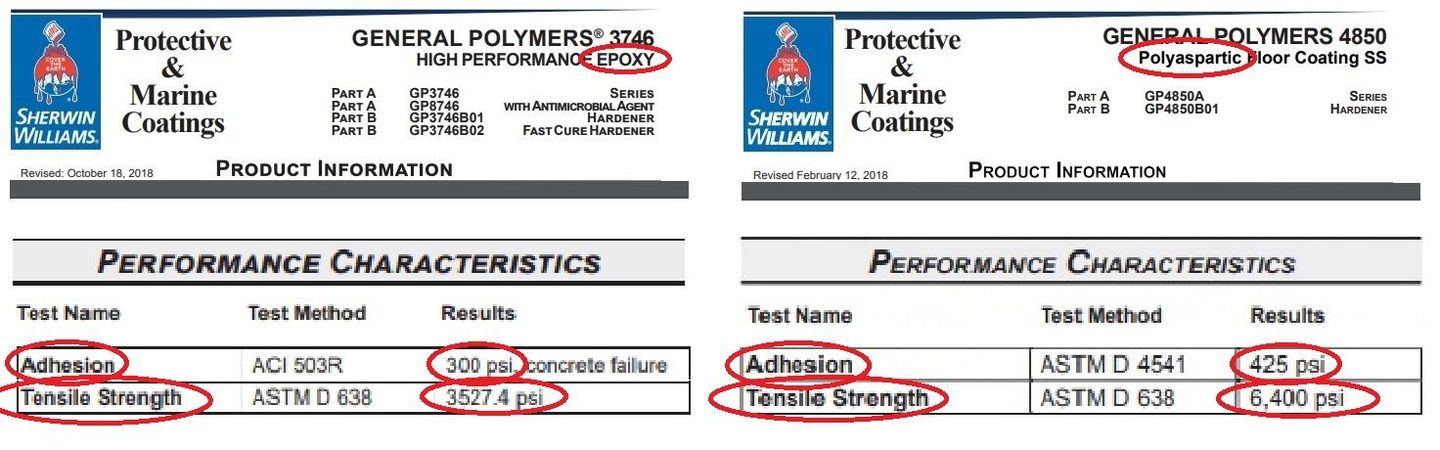

Polyaspartic instead of Epoxy because it Sticks 141% Better & is 181% Stronger according to Scientific Product Spec Sheets (here) and it's Flexible unlike Epoxy so it Does Not Crack over cracks in your concrete slab like epoxy naturally does as seen in this YouTube Video Here!

PLUS our Polyaspartic can be Parked on in ONLY 12 Hours! YES! In 12 Hours after we apply the clear coat you can move your refrigerator, work bench, tool box and even your Truck on it! No Long Wait Time Like with Epoxy! We install 2 & 3 Car Garages in a Single Day all the time, so you could have been driving on your new floor tomorrow morning if you had scheduled us to start today! Plus our Polyaspartic Floors include a LIFETIME WARRANTY AGAINST PEELING! Why Wait? Schedule us for a 1 Day Polyaspartic Heavy Flake Floor TODAY!

CALL NOW 281-849-3070

$2,495 - 2 Car Garage (First 400 sq ft)

$3,495 - 3 Car Garage (First 600 sq ft)

Only

$5.95 Per Sq Ft Thereafter

Let's Talk About the Details:

-Diamond Blade Grinding

-ALL Crack & Hole Filling (we fill ALL CRACKS & HOLES)!

-10 Dry Mils of 100% Polyaspartic Coating by Labsurface instead of epoxy because it's Flexible, Stronger and Sticks Better than Epoxy SEE PROOF Right Here on the Spec Sheets.

-Two Layers of Chips Right on Top of Eachother. We put the coating down so thick that the first layer of chips that are thrown soak down and go inside the coating while we are throwing more on top of them (as seen in this video here) they are pushed down and the next layer of chips sits on top of the coating so that after you wear past the first layer in several years from now it will expose more chips that match the rest of the floor instead of showing the solid color polyaspartic coating that was put down before the chips so that you do not have solid grey areas on your floor where you used it the most. Well you will later, but it will take twice as long to get there as it will the competition. We offer you the Most Value for each Dollar Spent, because the more material you have between your feet and the concrete the longer it will take to wear down. See how many chips we use on this Youtube Video HERE!

-Clear Top Coat of 100% Labsurface Polyaspartic at 10 dry mils Thick. 10 Dry Mils of Clear Coat is a significant amount of clear coat. Our Floors have enough Clear Coat so that it is not ruff and jagged but smoother like an orange peel. We Offer the MOST VALUE! No Company Offers a More Valuable Floor than we do.

-LIFETIME No Peel Warranty Included

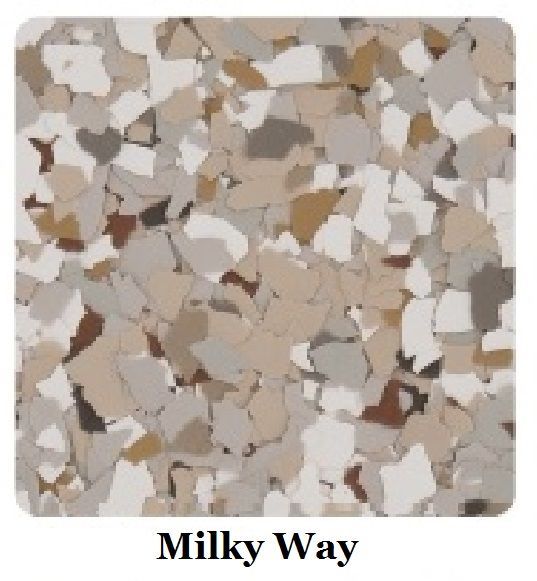

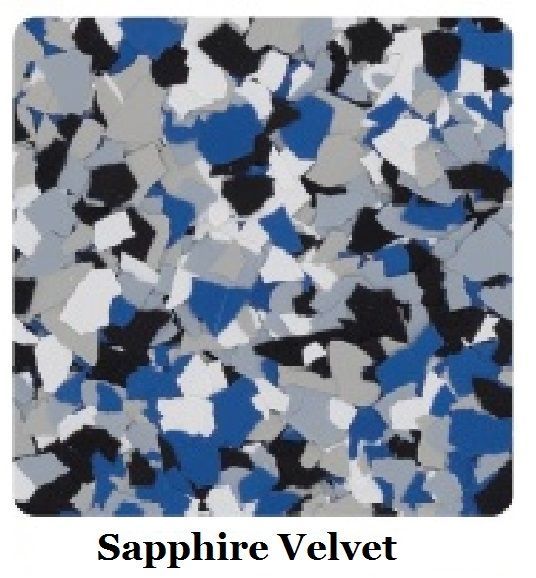

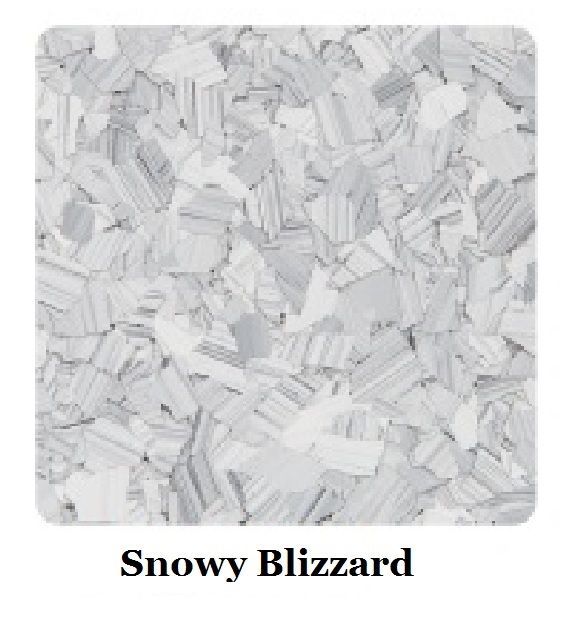

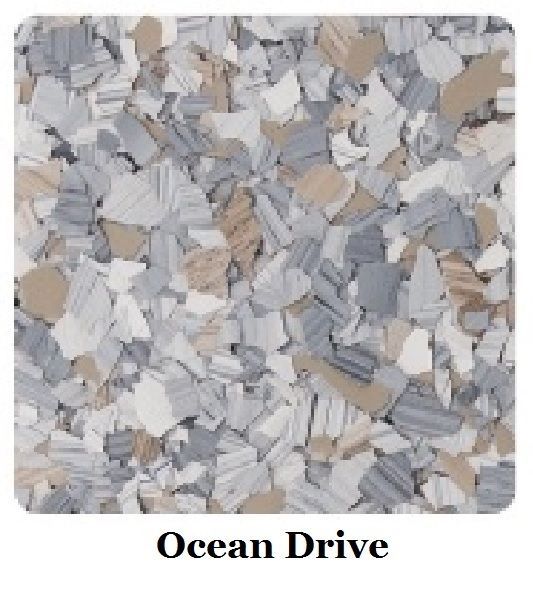

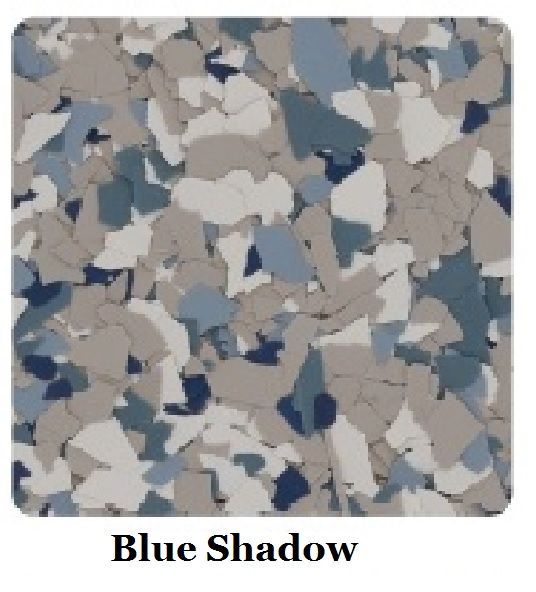

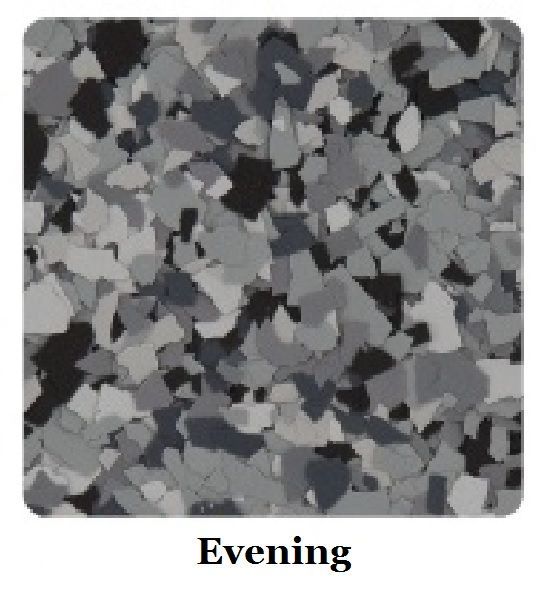

-Pick One of the Color Blends Below or on the Gallery Page

Meet The Owner

Donald Eugene Sanderson Jr Started installing Garage Floors in 2003!

Hi my name is Don and I was born and raised right here in Houston Texas USA! I installed my first garage floor 21 years ago (in 2003) but I'm still excited about garage floors! I first fell in love with epoxy while being taught the science of resinous two part cast molds in my 8th grade shop class while at Bleyl Junior High School in Northwest Houston way back in 1996! I graduated from Cypress Creek High School in the Class of 2000! Go Cougars! I then went to Lone Star College in Tomball when it was just called "Tomball College," I was the Vice President of Campus Crusade for Christ my first year there and for work I did odd jobs and handyman/home remodeling on the side. In 2003 I finally got that opportunity to install garage floor epoxy at a dry cleaner that a friend owned. I had been dreaming of this day ever since Junior High School! The Home Depot had just begun to sell garage flooring epoxy box kits and my friend Wes who I worked for periodically asked me to install epoxy on the floors of his new dry cleaners location in the Champion Forest area off of Louetta Road. The floor was a total sucess, his customers loved it so much that they started to ask for my phone number so that they could hire me to do their garage floor too!...and that's how I started!

I struck dozens of deals because of that floors location. So after building some experience on several garage floors and acquiring the technique of throwing the chips into the floor in a uniform manner (it takes a long time to learn how to do it right) I stuck a sign on the side of Louetta Road in NW Houston that said Garage Floors with my phone number on it, and I was in business! At first I just did floors on the weekends and in the summer because the demand for this was very low at the time. Eventually in 2010 after 7 Years of doing it on the side I was getting so many requests that I felt safe quiting my day job as a cost engineer and doing garage floors full time! (I did however take a brake from Garage Floors from 2006 to 2008 because I went to Iraq to do construction related contract work for the US Airforce and Army.) It was an honor to help our Troops so that they could go fight for us.

When I decided to go full time in 2010 I had already been previously thinking about changing my business name from Epoxy Pro to Houston Garage Floors because the more I learned about epoxy the more I realized how problematic it was. I had regretted putting the word epoxy in my business name because, ironically the more I became a pro at epoxy, the more I realized how inferior it was, I had to change my business name and I had to do it fast. I loved Garage Floors and I wanted to stick to residential work because I knew that my attention to details would shine their, so I picked the business name that best described what I did and where I did it HoustonGarageFloors.com

If you want to read about my progession from using Rustoleum Epoxy Shield box kits from The Home Depot to the commercial grade polyaspartic we now use, you can read my FREE 10 Page Book https://thebookongaragefloors.com/

22 Years of Garage Flooring Experience & We are Here to Stay! The Best Polyaspartic Garage Floors that Houston Offers

If you are looking for the best Garage Flooring in Houston then look no further than Houston Garage Floors! We specialize in providing premium quality polyaspartic coatings (better than epoxy) because Polyaspartic is 2x Stronger than epoxy floors and it sticks 141% Better (as seen in the product data sheets above) PLUS you can walk on our garage floors in 2 hours and drive on them the very next morning (12 hours later) GUARANTEED! Epoxy takes (72 hours) before you can drive on them! Our polyaspartic coatings are tougher, more durable (3x the durability of epoxy) and they're easy to clean and maintain because they are relatively non-porous unlike epoxy which stains super easily. There are many reasons why our polyaspartic (urethane) floor coatings are better than epoxy but the most important reason is that it does not crack over cracks like epoxy does. Epoxy is not flexible but polyaspartic is, so if you put epoxy over a filled crack (all cracks move) then the epoxy will buckle and crack with the crack when the crack moves because the epoxy has no choice since it is not flexible. Polyaspartic flexes unlike epoxy which prevents these types of floor coating failures that are common with epoxy.

Another great benefit of our exclusive heavy chip polyaspartic flooring is that it is slip-resistant because of the large amount of decorative chips (flakes) we put into our floor. No one puts as many chips into their floors as we do, other companies lightly sprinkle the garage floor with chips in order to barely cover the surface so that it looks like a saturated floor but we actually saturate the floor with chips until rejection, which means we have chips below the chips unlike any other company. We use one quarter of a pound of chips per each square foot which is four of the 5 Gallon Home Depot Orange Paint Buckets for a 2 car garage and six of those buckets on a 3 car garage! This ensures that you not only have chips on top, but that the coating itself is saturated with chips so that when you wear thru the chips on top you have more chips below for twice the life span. Adding chips makes your floor look beautiful and gives it a natural stone or terrazzo appearance. The chips are also important for safety reasons as they add grip to your feet because you don't want anyone slipping and falling on your garage floor. All of our Heavy Chip garage floor packages have an orange peel texture and exceed ADA requirements for slip resistance. For samples call us or email us and we will let you see and feel our floor samples so that you know exactly what you are getting before you make a purchase. Call us today to get a FREE estimate and floor inspection that includes a free moisture reading on your concrete! CALL NOW! 281-849-3070ttps://w cww.surfaceprosepoxy.com/

There are many benefits to having the garage floor that Houstonians love!

- Durability: Polyaspartic is the most durable flooring material on the market, and it can withstand heavy traffic and abuse because it is resilient (slightly flexible) unlike epoxy which is brittle. This means when you drop something on your polyaspartic floor it will give instead of resist and crack like epoxy. This is also important if you have cracks in your garage floor. All cracks move. If you have something non-flexible over your crack like epoxy then it will crack and buckle with the moving crack. Polyaspartic will move with the crack unlike epoxy. This is why epoxy has such a bad reputation for cracking & chipping.

- Strength: Polyaspartic is much stronger than concrete (20x stronger) which means it can withstand impacts better than concrete.

- Sanitary: Polyaspartic is non-porous and seals the porous concrete which traps grime and dirt easily and gives bacteria a place to grow. Sealing your garage floors and eliminating the porous concrete is the healthiest option. Epoxy is porous, which means it can hold bacteria, grime and germs.

- Safety: Concrete naturally chalks (creates dust) which you bring with you into your home on the bottom of your feet. Concrete dust is hazardous in nature and contains cancer causing carinogens such as silica and hexavalent chromium, this is why we use P95 respirators when preparing your concrete. Sealing the concrete stops this hazardous dust from coming into your home every single day which could otherwise make you ill.

If you are looking for the highest-quality, most durable and beautiful garage floor coatings that Houstonians love, we are the right choice for you. Contact us today to schedule your free no-pressure consultation!

Polyaspartic Garage Flooring Services...

We Provide the Highest Quality Most Detailed Garage Flooring that Houston Residents Need

If your garage flooring is in need of an upgrade, and you need it installed in with Attention to Detail then look no further than us because we provide the highest quality garage flooring Houston residents have seen! Our Heavy Chip Floors that contain Polyaspartic (urethane) on top and on the bottom (instead of epoxy) coatings can be walked on in 2 Hours and driven on in only 12 hours Guaranteed! Most companies just put urethane on top of the chips but our premium fast drying and stronger floors contain polyaspartic (urethane) directly to the concrete as well. Polyaspartic is stronger, sticks better (as seen in the data sheets above) and dries faster allowing customers to walk on the floor the same day as the Clear Coat is installed and drive their cars on it the very next morning (ONLY 12 hours later) because there is no epoxy below which requires more time to dry. But more importantly polyaspartic is flexible unlike epoxy which is brittle therefore polyaspartic will not crack like epoxy does over concrete cracks. All concrete cracks change in size daily as the temperature changes from sun up to sun down which causes the bridge on top (epoxy or polyaspartic to experience stress.) This is why epoxy floors more frequently experience buckling over cracks as they have no flexibility unlike polyaspartic. Watch how epoxy snaps like a potatoe chip over cracks in this informative video! Polyaspartic coatings are also UV stable unlike epoxy which turns chalky and eventually shatters like lawn furniture when exposed to any form of light. Polyaspartic (Urethane) coatings provide the ultimate protection against wear and tear, making them the ideal garage floor coating Houston TX home and business owners love.

There are many benefits to upgrading your garage flooring, including improved aesthetics, cleanability (no more concrete dust in the house), walkability (you can walk on our floors with bare feet without scratching your feet because we use the most clear coat), and higer home resale value! If you're tired of looking at cracked, stained, or otherwise damaged flooring, then it's time to give us a call. Don't settle for less than the best when it comes to the garage flooring Houstonians desire. If you choose an inferior product like epoxy and it fades, cracks and chips then you will have wasted all of that money, plus you will have to pay $3 per square foot to have the failed epoxy removed (about $1,200.00 for a 2 car garage) then you will have to pay for a new floor. The difference in cost between epoxy and polyaspartic is not just the polyaspartic floor minus the epoxy floor cost, but it is also the removal cost, plus the cost of the epoxy floor that was removed. You will have spent 3x as much money getting epoxy after it fails, and it will fail, it is designed to do. If you can't afford to do this right now, then just wait a little longer until you have enough money to do it right the first time otherwise you will be throwing good money down the drain. Our call us and see if we can work with you on the credit card fee so that you can finance it on your credit card. If you are moving into your home we recommend doing this before you move your stuff in otherwise you'll have to move everything back out and then back in again. Time and labor cost money. Contact us today and get a free quote. We look forward to serving you! 281-849-3070 CALL NOW!

The Ideal Material for Houston Garage Floors

Concrete floors in garages see a lot of wear and tear over time as the hot, humid climate combined with heavy traffic can take its toll on even the most well-constructed floor. That's why it's important to choose the right flooring material for your garage. There are two main types of garage flooring on the market today: epoxy and polyaspartic (which is a type of urethane.)

Epoxy is not a flexible product, it is brittle so it is not ideal for concrete floors with cracks. This is because concrete cracks move and if you have epoxy (which is not flexible) in the crack or over the crack then it may buckle and peel when the crack moves. All concrete cracks move every single day because of thermal expansion, the temperature causes the concrete to expand during the heat of the day and shrink at night when it gets cool. Filling or covering cracks with typical epoxy is like filling or covering cracks with potatoe chips, they can't handle the stress and will chip, buckle and peel as seen in this video. Polyaspartic urethane does not crack over concrete cracks like epoxy does because it is a flexible product. Polyaspartic is also less susceptible to staining than epoxy because it is much less porous than epoxy making it an excellent choice for high-traffic areas. To top this all off polyaspartic is 2x stronger than epoxy and it also sticks 151% better to concrete! Epoxy is literally designed to fail. If you're looking for something that you want to last more than a couple of years then polyaspartic urethane meets your needs. Epoxy is a maintenance solution, and something that needs to be re-done every few years, which is why it is so cheap. We know this because we started our business installing epoxy in 2003, but after years of seeing customers with floors that cracked over the concrete cracks we decided to change our name from Epoxy Pro to Houston Garage Floors in 2010. We did not want our name to be tied to an inferior product. If you want to read our short 10 page story that tells you what materials we started with and the problems we had with them you can read our free book. It explains the thought process we went thru while trying to perfect the garage floor. There were not many companies in Houston doing epoxy flooring when I started 21 years ago and none of them were dedicated to only doing garage flooring. We had to learn thru experience. Learn from our expense for FREE! That's why we call it The Book on Garage Floors. (TheBookonGarageFloors.com)

We don't like making mistakes but 21 years ago there were no books or youtube videos in this industry. We don't want anyone to get their garage floor done the wrong way, it costs too much heart ache, time, energy and money to re do a floor. This is why we give you all of our garage flooring insights and secrets for FREE! Even if you don't choose us to install your garage floor please read this 10 page short book so that you can make an informed decision, we would hate to hear about another epoxy nightmare. It is only a 10 minute read that could literally save you thousands of dollars:

Go to:

TheBookonGarageFloors.com